INSTALLATION WITH ROLLERS

The pod, unloaded with a crane or forklift truck, will be positioned onto special rollers (supplied by the manufacturer) in order to be rolled into its final position.

If an uncovered overhang in the building is not available, it will be necessary to provide an adequate landing platform applied and secured to the side of the building and then moved from floor to floor as the case will require. In this case the rollers will be placed on the platform and the pod will be slowly positioned on them by the crane. Using the crane, once unscrewed the loops from the bushings, the polyethylene over the holes must be restored and lacerations caused by the loading must be repaired.

For low height building operations can be simplified by lifting the pods to the floors by means of telescopic forklift for the subsequent rolling phase.

Three rollers are needed: two fixed rollers placed near the back corners of the pod and one steering roller platform placed at the front, in central position so that it can be steered easily. Pods must be laid on steel, concrete, plastic or neoprene pads with thickness and position prescribed by the manufacturer according to the assembly requirements (in the picture you can see some pods in their final position and other ones stored).

During rolling of the pod it is important that the route is smooth, leveled and free from any openings such as ducting shafts, so the rollers can run freely along the surface. To move and steer the pods 3-4 people are necessary.

In special cases, such as for example low interstorey height, special rollers/wheels will be applied to the sides of the pod’s structure instead of under the base.

Smaller pods can be rolled to their final position just with an electric pallet truck with forks long enough to reach the back wall to avoid distortions and damage to its base.

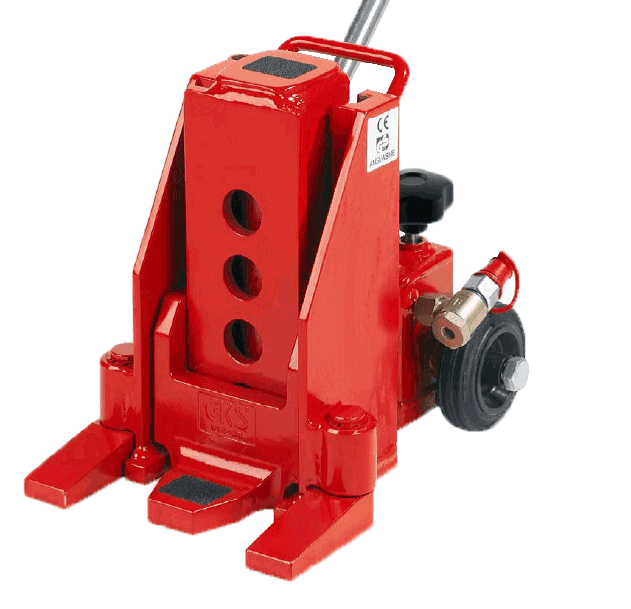

When the pod is in its final position, the rollers are released by means of standard hydraulic jacks.

In any case, it is important to check that the surface under the pod is perfectly level to avoid any distortion.

INSTALLATION WITH CRANE

This is by far the easiest and quickest method and only few precautions are required to achieve a perfect installation. Just three people are required: one maneuvering the crane and two people accompanying the pod to its final position and giving instructions to the crane operator.

Even in this case the pod must be laid on steel, concrete, plastic or neoprene pads with thickness and position prescribed by the manufacturer according to the assembly requirements.

If necessary, installation by crane allows to easily manage pod’s positioning into any notches, depressions, basements, thicknesses, platforms or hikes in the floor slabs.

Even in this case, once the chains are unhooked and the loops screwed out of their seats, it is necessary to patch up the holes or any accidental tears in the protective sheeting caused by loading.

SPECIAL ARRANGEMENTS

Once pods are installed, especially in a wet environment, the protection provided by the manufacturer must be left on and rather, it should be further protected with the additional polyethylene tarpaulins, or other weather-proof material.

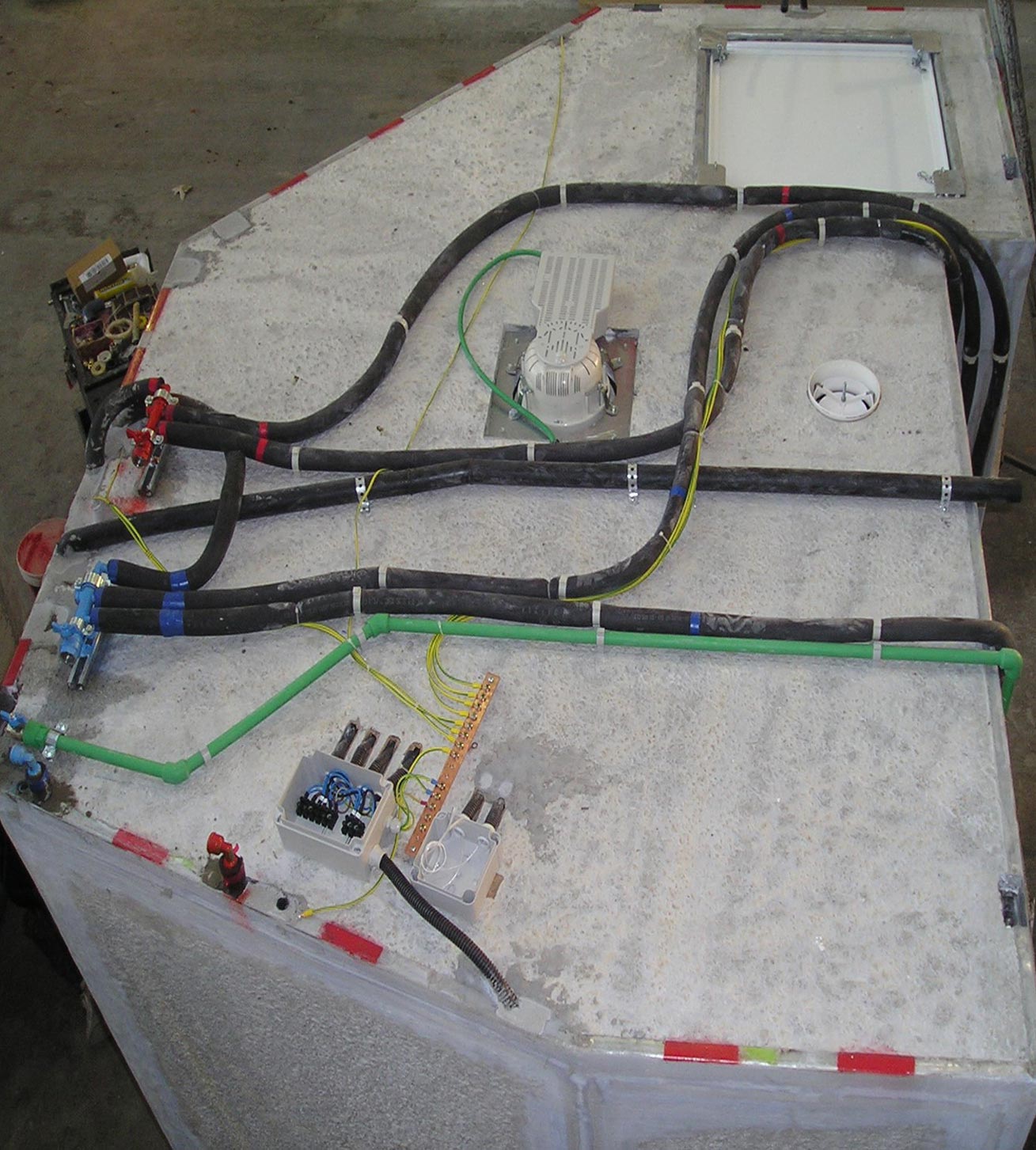

CONNECTION TO MEP BUILDING SERVICES

At this point bathroom pods have been installed and are ready to be connected to the MEP building services.